Yep, another cooking analogy for y’all. Since we are still in the holiday season or, at least, holiday adjacent, it seems like the right time for this one. Oh, yeah, happy New Year!

As you may remember from my “I Ruined Thanksgiving” blog post, I’m the main “food preparer” in the family. This means I’m subject to critiques that range from, “These are the best hash browns ever” to “Ugh, this has no flavor”. Such is the life of a creator, but I digress.

I like to think I’m the good kind of lazy (don’t ask my wife). I like working with people who are the good kind of lazy. By “the good kind of lazy”, I mean people who identify something that can be made more efficient and that efficiency also adds value to the company… or in this specific case, the family.

When cooking, I frequently try to use fewer bowls, utensils, etc. My theory, which is usually born out in practice, is that the fewer things I dirty, the less cleaning effort I have to expend, and the more time I can spend doing other things with the family.

Usually.

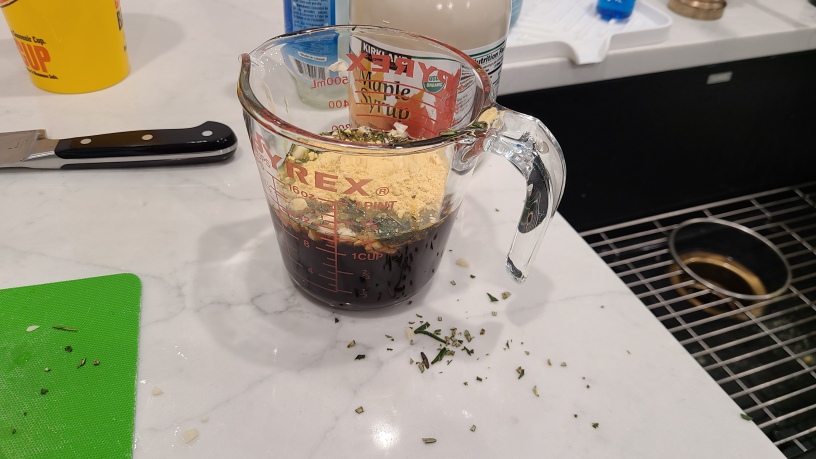

As you might be able to tell from this post’s image, I sometimes wind up making a bigger mess than the one I was trying to avoid. In this case, I figured I could just pour the chopped rosemary into the measuring cup; there was no need to dirty an additional mixing bowl. Clearly, I was mistaken. I wound up with a messier countertop and I had to work harder to get the rest of the rosemary into the cup. I wound up doing more work.

We often do this with test automation as well. We’ve acquired an automation tool, maybe we bought it, or maybe we used an open-source tool and built some stuff on top of it. Regardless, we have something in place (the measuring cup) and we don’t want to add additional effort (dirtying another bowl). But now we have to test a new technology (adding the rosemary) and we want to automate that technology using our existing tool (again, we don’t want to dirty another bowl), but our current tool doesn’t work well with all aspects of that new technology. Sometimes using our existing,”suboptimal fit” tool works out well, but sometimes it does not. Equating limiting our number of tools to limiting our effort, and therefore our cost is sometimes misguided.

Back to my cooking analogy, as it turned out, I would have needed less cleaning effort had I poured the contents from the measuring cup into a bowl with a wider mouth and then cleaned that bowl later; adding the spilled rosemary to the measuring cup was a pain.

Sometimes, the right answer is more than one tool. Looking back, I should have used the measuring cup and then a bowl with a wide enough mouth that would allow me to pour the rosemary without spilling it.

It’s the same with automation. We invested time and money into learning, implementing, and receiving value from our current automation tool. Of course, we’d prefer to keep using that one. To add a tool to our world, we’ll need to choose a tool, possibly purchase it, and learn how to use it before we can get any value from it. That can be a significant opportunity cost, at least in the short term. Perhaps we should just muddle along with our current tool even if it is a suboptimal fit. It won’t do as good of a job and, over time, it may cost us more via effort and missed opportunities than if we had added a new tool.

I’m not advocating using a new tool every time we need to automate something new; there is value in minimizing the number of tools in our toolbox. We should evaluate whether our current tool is appropriate for this new job. If it is not a great fit but appears to be serviceable, sticking with our current tool may be the best approach. We should note, however, what difficulties or issues we may encounter that can cause additional costs or risks due to our tool choice. If those costs or risks are intolerable, bringing in an additional tool might be the more appropriate decision.

Like this? Catch me at or book me for an upcoming event!

[[..Pingback..]]

This article was curated as a part of #118th Issue of Software Testing Notes Newsletter.

https://softwaretestingnotes.substack.com/p/issue-118-software-testing-notes

Web: https://softwaretestingnotes.com

LikeLiked by 1 person