Most people know nothing about the Dutch company ASML. This does little to dent the fact that it is the most important company in the world writes Satyen K. Bordoloi

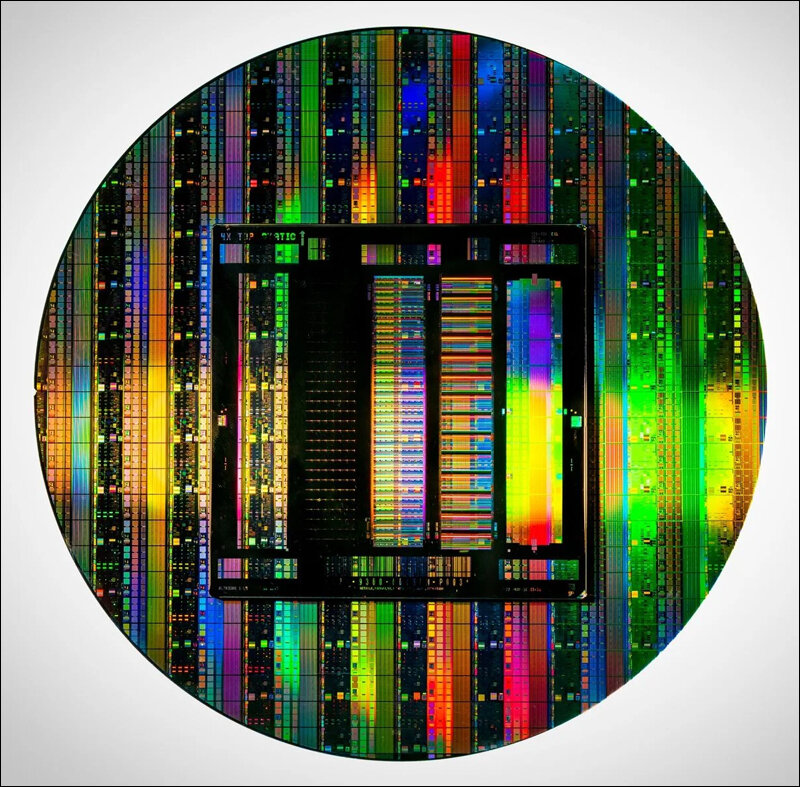

Do you know what is common to every electronic device in your home: from computers, TV and fridge to fans, mixers and lightbulbs? All of them have ICs or Integrated Chips, also simply called chips or microchips. Multiple miniaturized transistors and electronic components are integrated into one chip like the 5-nanometer Bionic chip in iPhone 13 and 14 have 15 billion transistors.

Some of the world’s most profitable companies are those that make these chips, from the most valuable – TSMC in Taiwan, to the legendary IBM. Yet, the most important electronic company in the world that sits slightly above on the food chain – yet few have heard about – is called ASML, headquartered in a little-known town called Veldhoven in the Netherlands.

(Image Credit: Wikipedia)

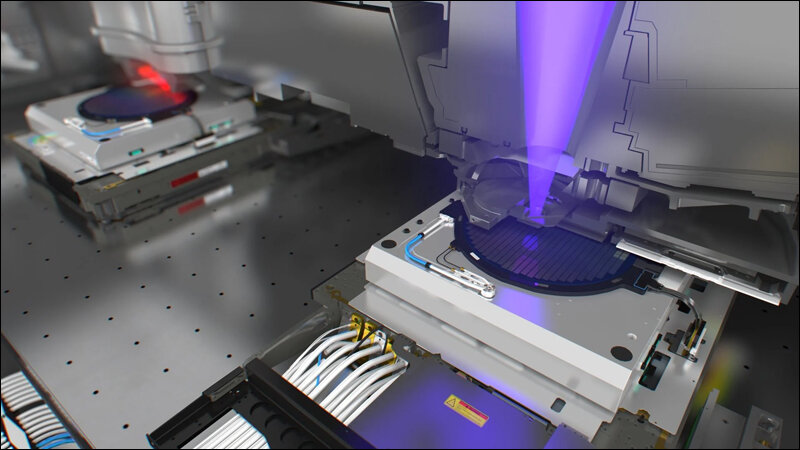

ASML specializes in the development and production of photolithography machines. Photolithography is a process of transferring patterns onto a substrate (usually a silicon wafer) using light. The photolithography machines produced by ASML are used to create patterns on silicon wafers, which are then used to produce the chips that power a wide range of electronic devices. These incredibly advanced and precise machines are critical tools in the manufacturing of microchips.

ASMLs technology and machines are key to the miniaturization of ICs while decreasing power consumption and improving performance. They are the reason your smartphone is not only hundreds of times faster and ‘smarter’ than supercomputers merely 30 years ago but also consumes a fraction of the energy.

ASML is the world’s only manufacturer of some of the most complicated machines ever made – the most advanced photolithography machines, each weighing 180 tons and selling for hundreds of millions of dollars.

How ASML became a Monopoly

(Image Credit: ASML Picture Park)

ASML began life in 1984 as Advanced Semiconductor Materials Lithography – a joint venture between Dutch electronics giant Philips and ASM international to make semiconductor equipment. But what it made initially was antiquated on arrival and the company struggled to find customers. As this 2020 Economist article points out, the firm “was kept alive by Philips, itself facing financial difficulties, and by subsidies from the Dutch government and the EU’s predecessor.”

The company went public in 1995 and decided to bet on EUV lithography. Extreme Ultraviolet Lithography is a technique that uses extreme ultraviolet (EUV) wavelength to produce a pattern by using a reflective photomask to expose a substrate covered by photoresist – a light-sensitive material. But EUV light with a wavelength of just 13.5 nanometres (one billionth of a meter) is extremely difficult to work with. However, shorter wavelength allows the etching of smaller components, crucial for making chips smaller.

Hence, the company took longer than expected, debuting their first prototype machines in 2006 whose commercial delivery did not begin until 2018.

Today though, it is the only company that manufactures these machines that are indispensable to making smaller and smaller chips that power everything from your devices to one-day nanorobots that will clean your clogged arteries.

Though ASML is not the only maker of photolithographic machines, being the only one to fashion chips using EUV means its shares have grown exponentially. It has around 90 per cent market share of the lithography market followed by Canon and Nikon. Its market capitalization as of early February 2023, is $287 billion, making it the world’s 29th most valuable company by market cap.

However, it is much more valuable than its market indices show as the largest chip manufacturers be it Taiwan’s TSMC, Intel or Samsung are as reliant on this one company, as the rest of the world is on them to make the chips that run the world.

Since neither Canon nor Nikon is attempting EUV technology in their machines, ASML is expected to enjoy a monopoly for some time.

The Chinese Threat

China is the only competitor to ASML’s dominance as the Eastern giant has made no secret of its ambition to promote homegrown chipmaking firms to take on the likes of TSMC and Intel. Photolithography machines are key to this. This is an ambition America is doing its best to arrest. The Economist notes that though in 2018 ASML received a EUV machine order from China, the Dutch government did not grant ASML an export license ‘under American pressure.’ It has also alleged that “six employees, including some Chinese nationals, were involved in pilfering trade secrets from its American office in 2015. The firm disputes the suggestion that the theft was linked to the Chinese government.”

Just a couple of weeks ago, ASML’s CEO Peter Wennink told Bloomberg that China has no option but to compete with the world. But if US forces them to block sales of ASML machines, “they will develop them themselves. That will take time, but ultimately they will get there.”

However, these machines are extremely difficult to reverse engineer. Not just because of their complexity but because the components for them come from over 5,000 suppliers spread across the world. And even if China or someone else do manage to figure it, by the time they do, ASML themselves would have moved on. They are already working on the next iteration to better their machines.

ASML’s photolithography machines are not just at the forefront of technology, they’re constantly pushing the boundaries of what can be done. Its commitment to innovation will not only allow it to maintain its position as a leader in the semiconductor industry for many years in the future, but it’ll also be the key to a rapidly technologically evolving world.

Hence it is one of the ironies of life today that very few of us have heard of the company which literally affects the lives of every single one of us. But ASML wouldn’t mind. Their homepage says: “Changing the world, one nanometer at a time.” That, I am sure, would be enough for them.

In case you missed:

- The Robotics Revolution All Around We Don’t See

- One App to Rule Them All: The Phenomenal Rise of Super-Apps

- In-pocket Nuclear Batteries Threaten to Change World Order

- Is DNA-based Computing the Future of Our Digital World?

- PSEUDO AI: Hilarious Ways Humans Pretend to be AI to Fool You

- Why AGI, superintelligence fears for AI are unfounded

- Artificial Leaves Fight Climate Change, Become Future of Energy

- Personal AI’s Future Is Here: Not What You Expected; Close to What You Need

- Did Apple just invent the invisibility cloak with Vision Pro?

- 2023 Developments That’ll Alter Your Future Forever