Built Robotics has developed the first fully autonomous piling machine to tackle utility-scale solar foundations.

Using the Built Robotics RPD 35 autonomous piling machine, solar farms can be constructed up to five times faster than with traditional means and methods.

Piling is a complex construction activity at the heart of every utility-scale solar project. The piles required for solar panels are generally steel H-beams that measure 3.6 metres to 4.2 metres long and weigh as much as 90 kg each.

A typical solar farm requires tens of thousands of piles to be installed, each of which must be driven into the ground upwards of 2.4 metres and positioned at an accuracy of less than a couple of centimetres. Together these piles form the structural foundation of the solar array.

“Solar piling is a tough, repetitive job, one well suited to automation,” said Noah Ready-Campbell, founder and CEO of Built Robotics.

“Our piling robots will dramatically improve the efficiency of workers on jobsites, which is critical in the chronically tight construction labour market. And just as importantly, they will take people out of harm’s way, reducing noise exposure, strain, struck-by and pinch hazards.”

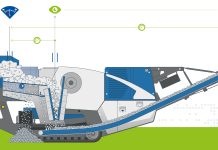

With the RPD 35, a two-person crew can install more than 300 piles per day, while hitting the most stringent tolerances on the market. This is achieved through Built Robotics’ Artificial intelligence software working in tandem with a custom pile cartridge system and advanced sensors like RTK GPS.

“The RPD 35 robotic pile driver takes four steps in the solar process, survey, distribution, driving and inspection, and kind of collapses them into one machine,” said Erol Ahmed, Director of Communications at Built Robotics.

The tracked machine includes two sleds on each side that carry a combined 200 piles.

“What’s cool about this is it’s our first foray into kind of doing custom hardware as well. We developed the hammer, the sleds and the basket system,” Ahmed said.

Robotic equipment operator

The difficult nature of pile installation has translated to labour shortages for the task. As the RPD 35 eliminates manual labour required for solar piles, skilled labour can tackle other jobs in a solar field.

“It’s a grueling task. You would rather have people working on more difficult skilled tasks. And now this kind of frees them up to do that,” Ahmed said.

As well, the autonomous pile driver potentially expands the number of working hours per day for a solar installation.

“The good thing about the robot is you could have it work at night, so the morning crews can come in and do their next steps. There’s a lot of opportunity with this,” Ahmed said.

Operation of the RPD 35 does require a Robotic Equipment Operator (REO) to handle logistics of the pile installations and ensure new piles are waiting when the RPD 35 needs to reload.

“We think this is the role of the future. People who manage robots will be trained in their operation, and they will set them up and get them going,” Ahmed said. “Usually when the robot is operating autonomously it doesn’t need human supervision. It’s hands off really. If it does need anything, it will let you know.”

Built Robotics history

The San Francisco-based Built Robotics entered the construction industry after developing the Exosystem, which transforms excavators into fully autonomous robots. The Exosystem can be installed within hours on various machines from most major manufacturers, while still maintaining complete manual control. Excavators equipped with the Exosystem are in the field for trench digging on energy and infrastructure projects.

“We started with trenching a few years ago, and that’s been really successful. … It’s trenching everywhere,” Ahmed said. “I think the power of our platform is you have software technology that can go onto almost any machine that enables autonomy. And then we just build off that for different applications.”

You may also like:

- Caterpillar autonomous solutions to be deployed in aggregates industry

- Attachments transform demolition robots into multi-purpose machines

- Trimble announces new Jobsite Connectivity software bundle

Built has a successful track record of developing robots for the solar industry, with its first commercial deployment occurring in 2018. Since then, Built’s robots have helped to install more than 2 GW of solar capacity across the country, enough to power more than 400,000 homes.

At the same time, the solar industry has advanced rapidly. Last year in the United States, about 10 GW of utility-scale solar capacity was installed. By 2030, projections show more than 100 GW will be installed each year.

“Solar is going to be huge, and we need robots to get there,” Ahmed said. “I don’t think we can build that much solar capacity with traditional methods.”

Built Robotics is scheduling the first customer deployments of the RPD 35 for the fourth quarter of 2023